EV Supply Chains Under Scrutiny: Rising Pressure for Ethical Sourcing and Compliance

The global automotive manufacturing industry is at an inflection point in supply chain management, driven by a convergence of unprecedented regulatory, geopolitical, and ethical pressures. Electric vehicles (EVs) are becoming a fixture of the modern automotive landscape – and with that ubiquity comes increased scrutiny of how their components are sourced, especially battery materials that could be linked to environmental or human rights risksAn urgent need for sophisticated risk management and compliance solutions, specifically focused on forced labor exposure, has surfaced. From U.S. enforcement of the Uyghur Forced Labor Prevention Act (UFLPA) to the European Union’s (EU’s) evolving battery regulations, companies are being held accountable for supply chain practices far beyond their direct suppliers.

As manufacturers navigate this complex landscape, advanced risk management and compliance solutions focused on forced labor exposure are essential to ensure ethical sourcing. Kharon offers forced labor solutions for risk management that help automotive companies meet rising due diligence standards across jurisdictions.

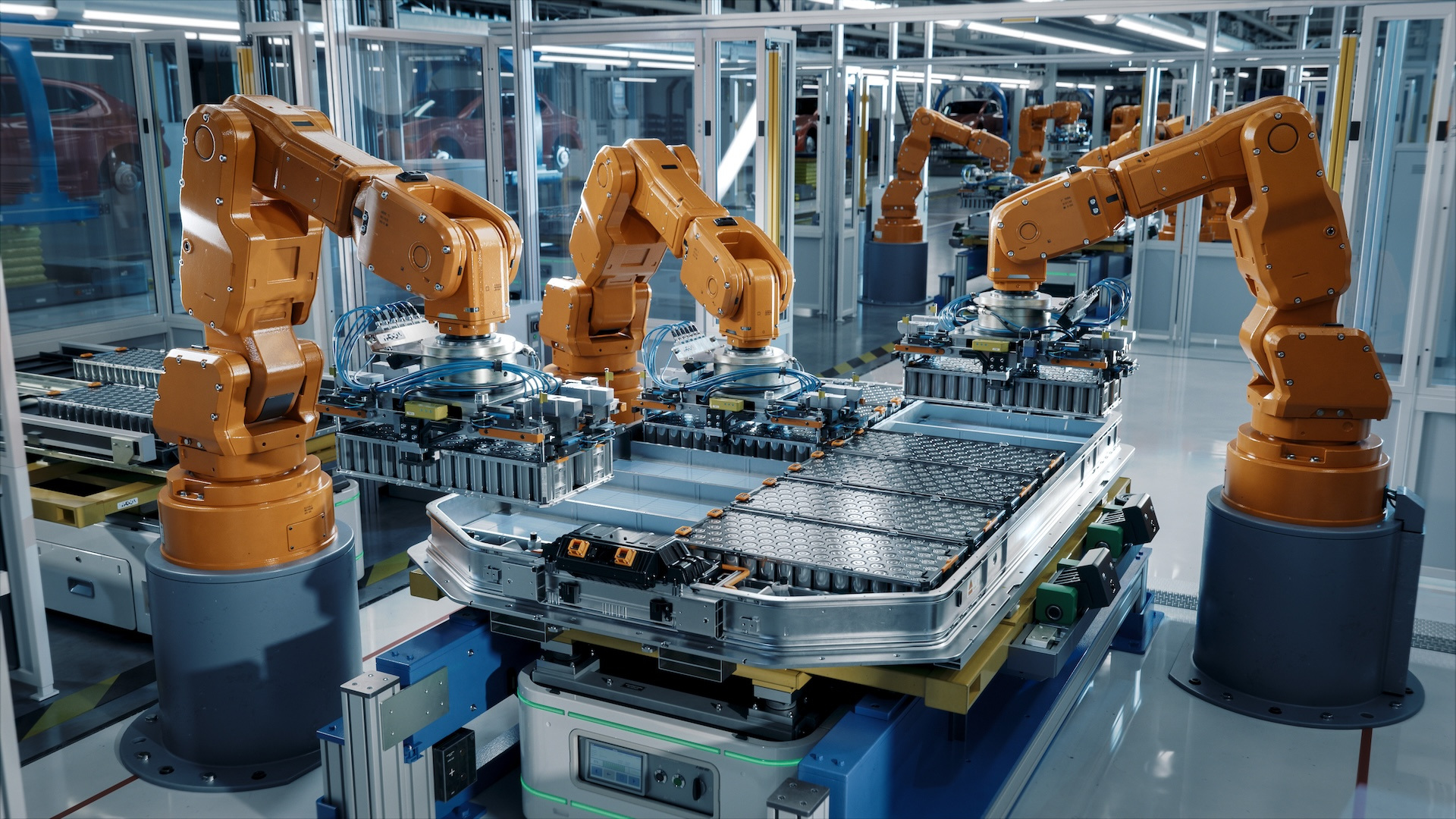

The Inherent Risks of EV Battery Supply Chains

In addition to relying on a complex network of suppliers, the EV battery materials supply chain is particularly vulnerable due to concentration in regions linked to human rights abuses, including forced labor.Other EV battery supply chain issues and vulnerabilities include:

- Lack of supply chain transparency beyond Tier 1 suppliers. While most manufacturers have visibility into their direct suppliers, it is incredibly difficult to ascertain the true origin and labor conditions of materials from sub-tier suppliers.

- Heavy reliance on foreign processing facilities. A significant share of battery-grade materials, such as lithium, cobalt, and graphite, are refined in regions where there are credible allegations of forced labor or lack of labor rights protections, including Xinjiang.

- Trade routes that mask origin. Some suppliers engage in transshipment or relabeling practices to conceal the true origin of goods, making it difficult to verify compliance with UFLPA and other regulations.

To get ahead of these risks, many manufacturers are beginning to pilot traceability platforms and partnerships.

The Compliance Burden for EV Manufacturers

EV manufacturers face increasingly stringent expectations and responsibilities to verify that their supply chains are free from forced labor. Regulations like the UFLPA create a high burden of proof by presuming goods with any component parts originating from Xinjiang involve forced labor unless proven otherwise with clear and convincing evidence. Moreover, goods and suppliers that tie back to Xinjiang can be masked through production facilities in other regions and countries.This puts many EV automakers, who rely on dozens of suppliers, many of which source or process materials across opaque international networks, in a difficult position. Tracing compliance across multi-tier supply chains can be costly, time-consuming, and technically difficult. These pressures are only expected to intensify as new laws around supply chain transparency and conflict minerals take hold across the U.S., EU, and beyond.

But non-compliance is not a viable option for most organizations. The financial repercussions could be considerable, involving hefty legal fees, storage and demurrage costs, and foregone sales. In addition to these direct monetary impacts, businesses may experience operational setbacks.

Ensuring EV Battery Supply Chains Meet UFLPA and Forced Labor Standards

Manufacturers can significantly enhance their EV battery compliance by leveraging a proactive, intelligence-focused approach specifically designed for UFLPA and other forced labor regulations. Risk analytics platforms like Kharon can support early identification and mitigation of forced labor exposure, helping organizations go beyond static supplier assessments and outdated certifications to meet current compliance demands.Kharon provides industry-leading tools for vetting EV battery supply chains, with a focus on features that enhance compliance with UFLPA, like:

- Visualizing risk across multi-tier supplier networks: Kharon visualizes and analyzes complex, multi-tier supply chain relationships to identify potential risks beyond just direct vendors.

- Identifying forced labor indicators: Kharon flags entities exhibiting high-risk behaviors associated with forced labor and maps these insights to supplier profiles for proactive risk mitigation.

- Integrating with existing procurement and compliance workflows: Kharon is designed for seamless integration with supply chain mapping and traceability tools used to demonstrate due diligence in supplier vetting under the UFLPA.

Building a Compliant EV Battery Supply Chain

Advanced screening is needed within the EV battery space. EV manufacturers must treat forced labor risk management as a strategic imperative rather than a compliance checkbox.This means:

- Making the internal business case for investing in improved UFLPA compliance programs.

- Implementing advanced supplier screening and traceability tools to ensure ethical procurement and sourcing.

- Future-proofing compliance by leveraging predictive risk insights to spot risk indicators before they result in enforcement.

Forced Labor Compliance with Kharon

As UFLPA enforcement intensifies in EV battery supply chains, organizations need more than basic screening to stay compliant – they need contextual, actionable intelligence.Kharon’s forced labor solutions equip compliance teams to:

- Identify entities and networks linked to Uyghur forced labor risk indicators

- Mitigate supply chain risk management with multi-tier vendor maps

- Track evolving enforcement trends and regulatory updates

- Generate verifiable documentation to support detention rebuttals

Additionally, Kharon has partnered with the Automotive Industry Action Group (AIAG) to support the automotive sector in mitigating forced labor risk.

Stay ahead of UFLPA enforcement and use Kharon to build a defensible compliance program. Learn more about Kharon’s Forced Labor solutions here.