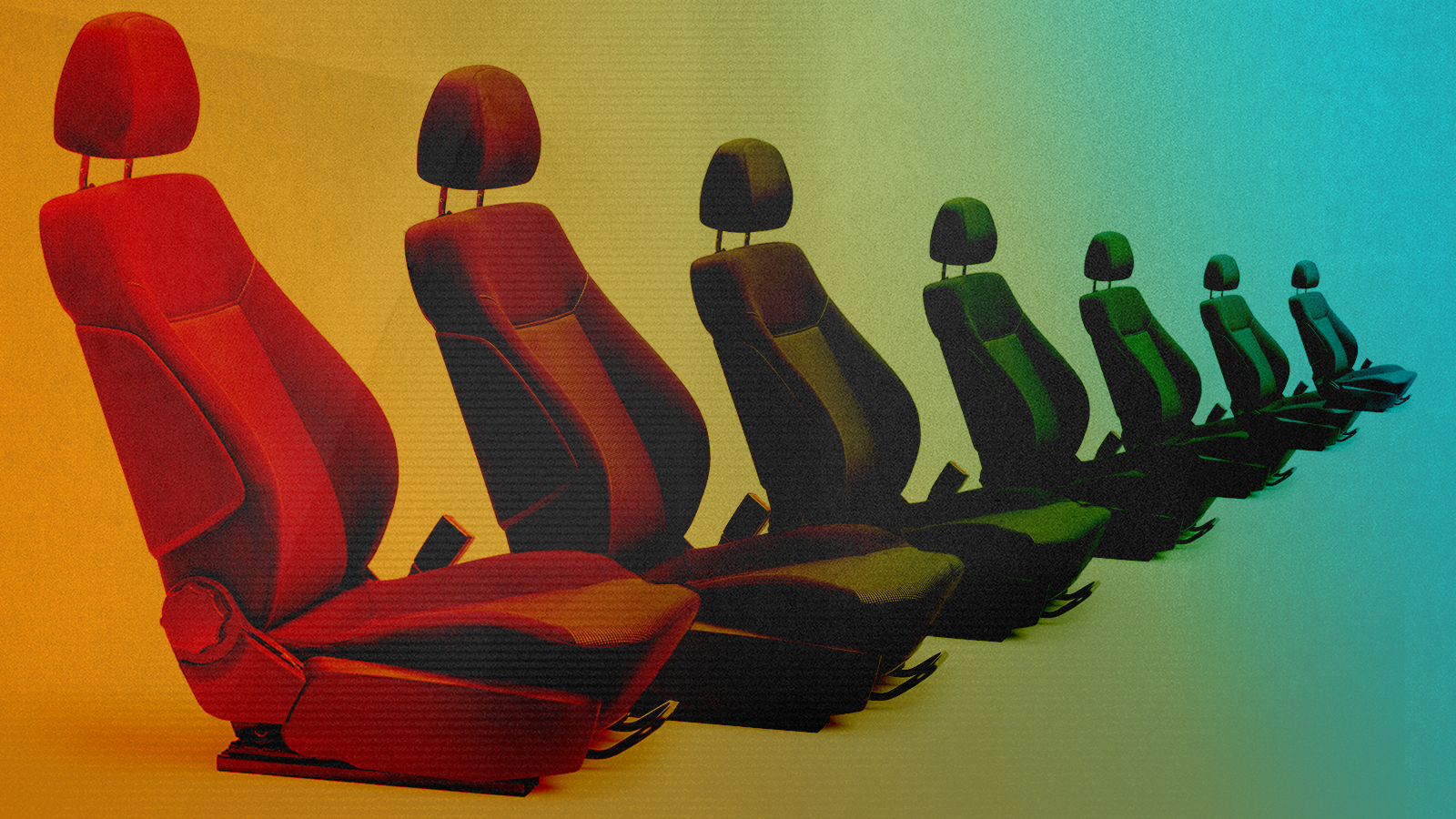

Wuhan Boqi Technology is a China-based automobile interior furnishings company that, according to its website, supplies major American, European and Japanese car manufacturers.

Boqi’s two largest shareholders have markedly different profiles. One is Sage Automotive Interiors, headquartered in South Carolina. The other is Wuhan Yudahua Textile and Garment Group, which is a significant supplier of raw materials to Boqi—and whose supply chain, a Kharon investigation found, connects to forced-labor-tied government initiatives in the Xinjiang region.

That raises the risk that red-flag textiles could be flowing through Boqi and into the cars of its global customers, at a time when auto imports have faced particular U.S. scrutiny under the Uyghur Forced Labor Prevention Act (UFLPA).

Boqi’s two largest shareholders have markedly different profiles. One is Sage Automotive Interiors, headquartered in South Carolina. The other is Wuhan Yudahua Textile and Garment Group, which is a significant supplier of raw materials to Boqi—and whose supply chain, a Kharon investigation found, connects to forced-labor-tied government initiatives in the Xinjiang region.

That raises the risk that red-flag textiles could be flowing through Boqi and into the cars of its global customers, at a time when auto imports have faced particular U.S. scrutiny under the Uyghur Forced Labor Prevention Act (UFLPA).

The Xinjiang supply chain

Wuhan Yudahua Textile and Garment Group’s network and suppliers include several notable touchpoints for Xinjiang cotton and fabrics:- It received a subsidy from the Xinjiang government for transporting cotton in both 2019 and 2020, the only two years for which such data was released.

- One of its wholly owned subsidiaries, Wuhan Yutaihua Trading, has at least three suppliers that have also received this subsidy, including one based in a high-risk Xinjiang industrial park.

- And a second subsidiary, Wuhan Yudahua Textile, wholly owns a Xinjiang-based procurer of textiles and fabrics, synthetic materials, chemical and petroleum products, cotton, and other raw materials called Xinjiang Yudahua Supply Chain Management Co., Ltd. It’s located in another industrial park with particular UFLPA risks—and Wuhan Yudahua Textile is its largest customer.

Kharon users can explore the Wuhan Boqi supply chain in greater detail through the ClearView platform.

Zoom in: That industrial park is the Kunyu Economic and Technological Development Zone, which is controlled by the Xinjiang Production and Construction Corps and was established through investment from the Beijing Xinjiang Aid Command. Both raise red flags for forced labor.

The Kunyu Zone hosts several companies, including textile companies, that have engaged in “poverty alleviation” and labor training programs that fit with further red flags the U.S. government included in the Xinjiang Supply Chain Business Advisory, or that have received Xinjiang Aid development funds.

Why that matters for automakers: This Xinjiang zone appears to be one potential origin point for Boqi Technology’s supply chains.

The Kunyu Zone hosts several companies, including textile companies, that have engaged in “poverty alleviation” and labor training programs that fit with further red flags the U.S. government included in the Xinjiang Supply Chain Business Advisory, or that have received Xinjiang Aid development funds.

Why that matters for automakers: This Xinjiang zone appears to be one potential origin point for Boqi Technology’s supply chains.

More connections to the U.S. and to Mexico

Boqi’s financial disclosures say that Sage Automotive Interiors, its U.S.-based No. 2 shareholder, is also a significant importer of Boqi products, along with Sage’s subsidiary in Mexico. (Trade records show that Sage Wuhan, a former Sage subsidiary now wholly owned by Boqi, has sent “100% polyester fabric for car seat” shipments to Sage, as recently as this month.)“Sage Automotive Interiors sources a very small quantity of woven synthetic materials from Yudahua’s operations in Wuhan China,” Sidney Locke, Sage’s vice president for purchasing, HR and communication, said in a statement to the Brief. “We have no connection to any operations in the Xinjiang area.”

By the way: Chinese auto manufacturers are increasingly setting up shop in Mexico themselves. As they do so, U.S. Customs and Border Protection reported that it detained five auto shipments from Mexico under the UFLPA in September, worth more than $2.4 million.

The forced-labor supply-chain risks here concern metals more than textiles. A Department of Labor report last fall noted both that Mexico “is now China’s leading export market for aluminum” and that “[a]pproximately 85% of the finished vehicles and auto parts produced in Mexico are imported by the United States.”

“There is a clear risk that forced labor occurring in the XUAR is finding its way into auto parts and vehicles produced in Mexico and subsequently imported by the United States,” the report says. “There is documented evidence of forced labor in the production of aluminum and auto parts containing aluminum from the XUAR.”

The bottom line

Rooting out auto-manufacturing risks under the UFLPA can require tracing through layers and layers of suppliers, all the way back to where certain materials are sourced.If a supply chain has ties to Xinjiang, that demands heightened scrutiny from importers. If those ties include the XPCC, Xinjiang government subsidies or other red-flag programs like Xinjiang Aid, those risks and demands grow higher still.